What you need for commercial kitchen extraction cleaning

Restaurants and Commercial kitchens

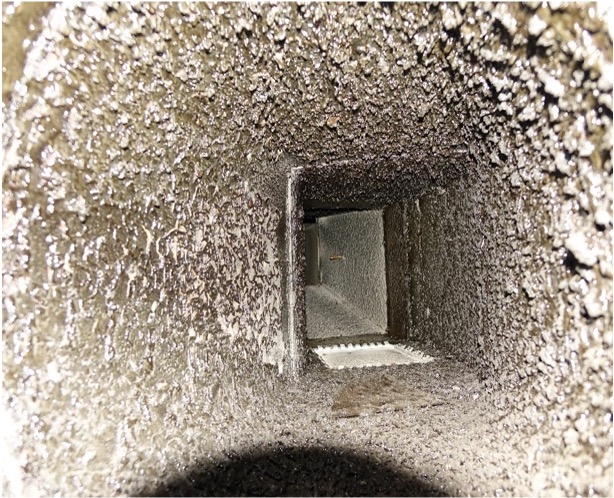

It’s important that restaurants and commercial kitchens perform kitchen extraction cleaning. This means removing grease and oil deposits from kitchen extract ductwork on a regular basis. Extract ductwork cleanliness is important for hygiene, but more crucially for the fire safety of the premises, staff, and customers. In this blog post, we’ll reference the relevant cleaning specification and introduce you to our line of rotary brush machines that are perfect for cleaning difficult-to-access areas of ventilation systems.

Regular Cleaning Schedule

Maintaining a regular cleaning schedule is vital to keeping kitchen extraction systems safe and compliant with regulations. Depending on the level of use, extraction systems should be cleaned at specific intervals:

• For heavy use (12-16 hours per day), systems should be cleaned every 3 months.

• For moderate use (6-12 hours per day), cleanings should occur every 6 months.

• For light use (2-6 hours per day), systems only need to be cleaned annually.

Establishing a proper cleaning schedule will help prevent the build-up of grease and ensure a safer kitchen environment.

What is TR19® Grease Specification?

The stand-alone specification TR19® Grease – Specification for Fire Risk Management of Grease Accumulation within Kitchen Extraction Systems is a document specifically focused on fire risk management of grease accumulation within kitchen extraction systems.

The TR19® Grease specification states that kitchen extraction systems must be cleaned regularly. The frequency of cleaning depends on the rate at which grease accumulates. A competent cleaning contractor should monitor how quickly grease accumulates within the system and advise the suitable frequency of cleaning. Kitchen extract systems should be maintained so that the thickness of the accumulated grease does not exceed 200 microns as an average throughout the system. Failure to maintain a kitchen extract system in accordance with TR19® Grease may invalidate the building’s insurance policy in the event of a fire.

Why Should I Buy a Rotary Brush Machine?

Contractors working in accordance with TR19® Grease often use a rotary brush machine or drill operated cable to ensure they can clean all areas of the ductwork system. By using a rotary brush with a long reach, it’s possible to clean long vertical sections (risers) fully and in a quick and efficient manner. Access panels should be fitted every 2m on the ductwork system, however these may require specialist access equipment to reach. Brush machines cut down on the need for specialist access, and reduce the amount of back-breaking work needing to be performed.

Professional Cleaning Equipment

To ensure thorough cleaning, professionals use specialised equipment like rotary brush machines with long-reach capabilities. These machines allow access to hard-to-reach areas of ductwork. Using multidirectional brushes is also essential, as they can clean all shapes of ductwork, including square and rectangular forms. The cleaning process becomes more efficient and less labour-intensive with hydraulic, electric, or pneumatic-powered machines.

Post-Cleaning Verification

After the extraction system has been cleaned, a post-cleaning verification process should be conducted to ensure that the job has been done thoroughly. This includes a visual assessment to ensure all surfaces are visibly clean, as well as conducting tests to verify that grease thickness is less than 200 microns throughout the system. A certificate or report should be obtained to confirm the system’s cleanliness, which can also be used for insurance purposes.

Why Should I Buy a Rotary Brush Machine?

Contractors working in accordance with TR19® Grease often use a rotary brush machine or drill-operated cable to ensure they can clean all areas of the ductwork system. By using a rotary brush with a long reach, it’s possible to clean long vertical sections (risers) fully and in a quick and efficient manner. Access panels should be fitted every 2m on the ductwork system, however, these may require specialist access equipment to reach. Brush machines cut down on the need for specialist access, and reduce the amount of back-breaking work needing to be performed.

Regular Inspections and Maintenance

In addition to regular cleanings, it’s essential to inspect kitchen extraction systems for mechanical issues, such as fan operation and filter functionality. Regular inspections help identify problems early, ensuring the system continues to operate efficiently and safely.

What Rotary Brush Machines Do We Offer?

Hasman offer a wide range of rotary brush machines, but the most suitable for kitchen extract cleaning are the Hydmaster40 (hydraulic motor), Special Cleaner 25 (electric motor) and the Combi Cleaner 15 (pneumatic motor). Our three motor options mean there is a solution for all preferences and site requirements.

The most powerful brush machine available on the market is Lifa Air’s patented Hydmaster40. Equipped with a 40m cable and powered by a hydraulic motor the machine is able to spin up to 3 brush heads, allowing the contractor to clean all shapes of ductwork with ease. The 40m cable is fitted with a fluid delivery line which allows foaming and rinsing of the ductwork while it is brushed.

Rotary brush accessories allow cleaning of all shapes and sizes of ductwork, these include 2-brush and 3-brush gearboxes which allow brushes to reach into the corners of square and rectangular duct forms.

Trained Personnel

It’s crucial to use trained professionals for kitchen extraction cleaning. These experts understand the intricacies of the process and can carry out the cleaning in accordance with TR19® Grease and other relevant regulations. Additionally, staff should be educated on daily cleaning routines for external surfaces to help reduce the build-up of grease and oil.

What About Drill Operated Equipment?

Drill operated equipment is also available for use on smaller systems or small sections of extract systems. The tough nature of the work means only extra strong cables are suitable in kitchen ducts, and they must be operated with suitable high-power drills. These cables are fully compatible with the full range of Lifa Air ductwork cleaning brushes.

Proper Cleaning Chemicals

Along with the right equipment, using the correct cleaning chemicals is vital. Degreasers and industrial cleaners that are designed specifically for kitchen extraction systems should be used to remove stubborn grease deposits and maintain the system’s efficiency.

So, You’re Looking for Kitchen Extraction Cleaning Equipment?

Look no further than our machines and equipment! For more information about kitchen extraction cleaning or to order one of our products, visit us online.